Mechanical Product Development Services

New Product Development & Prototyping

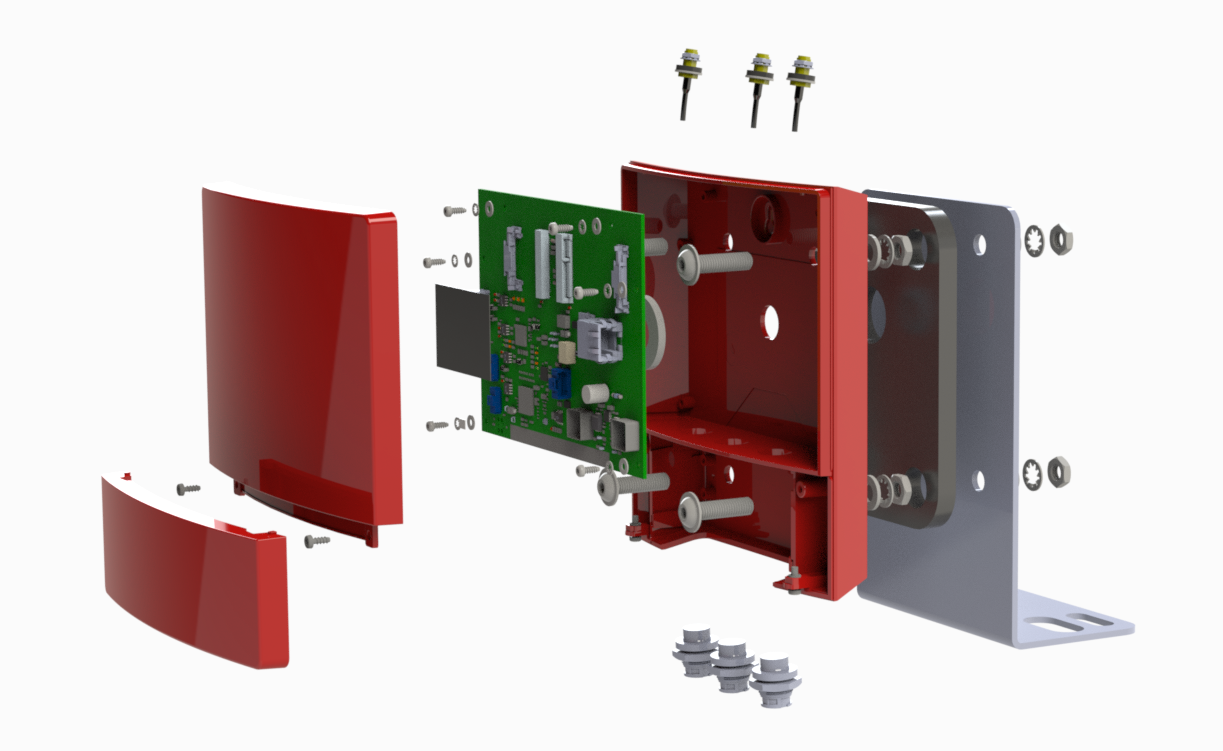

Rugged design for stringent environmental requirements

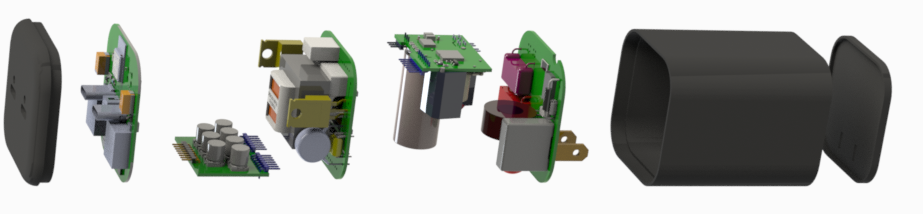

Complex electronics packaging in small envelopes

Design for Manufacture and Assembly (DFMA)

Capabilities

Rugged design for stringent environmental requirements (e.g. IP65-IP67)

- Human factors / user interface design

- SWaP (Size, Weight and Power) analysis and design

- Integration of electrical and mechanical parts and subassemblies

- Assembly jig / part fixture design and development

- FEA (Finite Element Analysis)

- Risk Analysis / DFMEA / PFMEA

- Root cause identification and problem solving with Six Sigma / Shanin methods

- Design For Manufacturability (DFM)

- Design For Assembly (DFA)

In-house 3D printing for prototyping and development

- Manufacturing quality system considerations

- Manufacturing supply chain vendor selection support

- Manufacturing process development

- SOLIDWORKS

- Autodesk Inventor

Mechanical Design Case Studies

Your deliverables are always ahead of schedule and of the highest quality.